With my platoon STLs sourced the next step is to resize, sort out supports and determine resin settings - which anyone who has used a 3D printer will know may well turn out not to be a walk in the park.

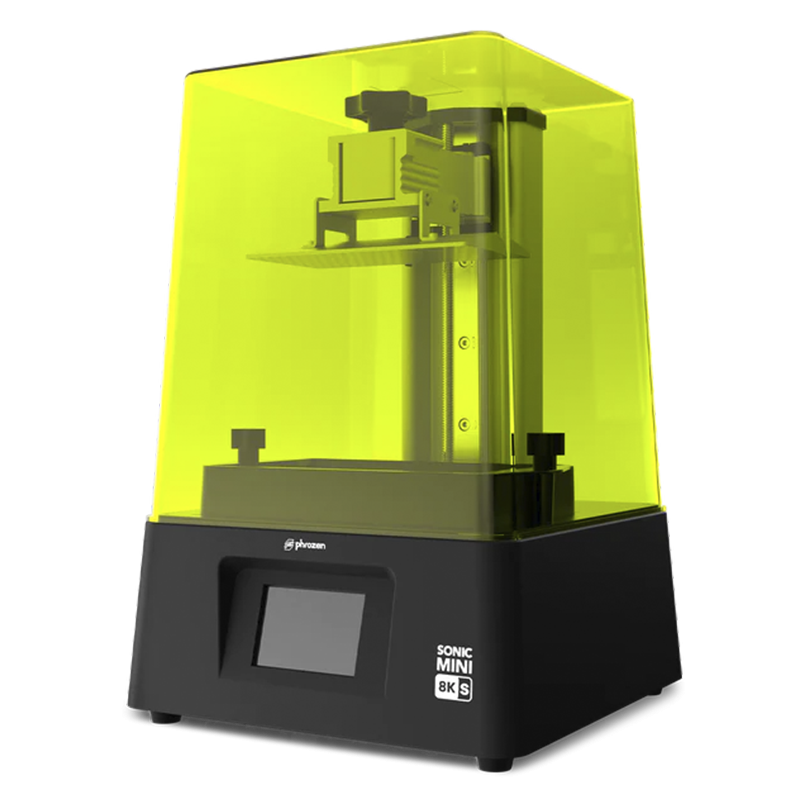

My 3D printer is Phrozen Sonic Mini 8K S printer which works for me as I have limited space on my desk. It has a relatively small plate as a result but produces excellent prints. I will be using Elegoo 8K Space Grey resin which I find to be a good balance of flexibility, resolution and of course, price.When resizing STLs I have found that some are more "heroic 28mm" than 28mm but I start with a 78% reduction and then compare to see if a further reduction is needed. With Colonel Muller's files a simple 78% is perfect.

I use LycheeSlicer to batch resize to 78%, repair where needed and add supports. This is where the resizing of files presents the first challenges: rifles and AT gun barrels can get very thin and I faced a challenge with the edges of some of the French helmets which would get damaged when removing supports after printing.

|

| The fiddly supports on the back of French helmets |

|

| Overview of typical supports |

I am printing at 0.025mm, so quite high resolution and near the maximum of the printer. As mentioned I support in Lychee, export to Chitubox and then create the print file.

After a lengthy printing (due to the resolution) and cleaning, I let them dry for a day and then a dip in very hot water before very careful support removal.

And voila!

|

| A finished print in 20mm |

No comments:

Post a Comment